To reveal important surface information (as described in the previous blog post), the coins have to be cleaned of surface dirt and corrosion products. This is done using a combination of two treatments; chemical and mechanical cleaning.

The photograph above demonstrates a typical example of the Frome coins once they have had an initial rinse in tap water and brush to remove surface dirt. The majority of coins in this photograph are covered in corrosion products rendering them illegible. These coins would first be treated chemically to reduce the majority of the corrosion products.

Chemical Cleaning

Two different chemical treatments are employed to clean the coins depending on the extent and type of corrosion present. After an initial visual assessment the conservator they will make a decision as to which chemical treatment is required. This is usually a treatment consisting of either a low percentage of formic acid, or an Alkaline solution, or both.

Chemical cleaning allows for large batches of coins to be cleaned at once, which is critical when cleaning such a large hoard. The conservator carefully monitors changes in the coins appearance and condition during chemical cleaning to ensure that the coins are not ‘over cleaned’. All coins which have been chemically cleaned are thoroughly rinsed with water to remove any traces of chemicals.

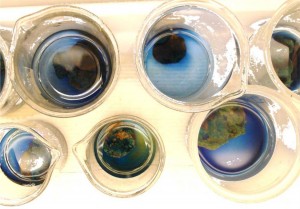

Coins in Alkaline Rochelle solution. This helps to reduce the level of blue/green copper carbonates.

Mechanical Cleaning

Mechanical cleaning is required when coins have small patches of corrosion obscuring important details. Coins with low levels of corrosion may not need chemical treatment, but will most likely require some mechanical cleaning. All coins which have been chemically cleaned require some form of mechanical cleaning.

Production line of Dremel rotary brushing.

Mechanical cleaning involves reducing corrosion products with a scalpel under magnification and brushing to remove surface corrosion product residue. The photo above shows a production line of conservators using natural fibre dental brushes, on rotary Dremels® . This allows for a greater quantity of coins to be brushed at one time, and is more efficient than brushing them by hand.

Following chemical cleaning corrosion and dirt residues remain on the coin. This coin has been brushed on one half to demonstrate the difference in legibility before and after.